There are many important characteristics in lens design, including lens resolution, lens distortion and illumination uniformity, which directly affect the performance of the machine vision system.

The cameras, lenses, and lighting used in machine vision systems all make important contributions to the overall image quality. The rapid development of CMOS image sensor technology in the past few years has brought major challenges to lens manufacturers. Higher and higher sensor resolution means that many sensors now have smaller pixels and require higher resolution lenses. On the other hand, a high-resolution sensor that maintains a larger pixel size for higher sensitivity usually uses a larger format, and therefore requires a larger format high-resolution lens. In addition, many applications that require very long focal length lenses, such as surveillance, sports, aerial photography, and photography on theme park amusement facilities, are increasingly being included in the category of machine vision and need to be addressed. Lens design including lens resolution, spatial distortion and uniformity of illumination through the lens have an important impact on the performance of the lens.

(1)Learn about Lens Performance-Modulation Transfer Function (MTF)

The ideal lens produces an image that perfectly matches an object, including all its details and brightness changes. In practice, this is by no means entirely possible, as the lens acts as a low-pass filter. Taking into account all aerations, the image quality of the lens can be quantitatively described by its modulation transfer function. MTF is defined by the ability of the lens to reproduce lines (grids) with different spacings (wire-to-space frequency/mm). The more pairs/mm of wires can be distinguished, the better the resolution of the lens. The MTF graph for each spatial frequency shows the loss of contrast caused by the lens (Figure 1). Large structures such as rough spacer lines are usually transferred with relatively good contrast. Smaller structures, such as thinly spaced lines, are transmitted with low contrast. The amount of attenuation of any given frequency or detail is classified by MTF, which indicates the transmission efficiency of the lens. For any lens, there is a modulation point of zero. This limit is often referred to as a resolution limit, typically referenced in lp/mm of line pairs per millimeter, or in the smallest line size (in sm) references to some macro lenses, which is equivalent to the minimum pixel size required for the lens. Appropriate. MTF's movement from the center axial edge of the lens deteriorates, which is an important consideration if the entire image requires a symmetrical resolution. Because like scattering, MTF can also vary depending on the direction of the line at a point on the lens and is also a function of the aperture setting when measuring, so care must be taken when comparing lens performance. Because the lens must be selected to match the resolution to the pixel size of the image sensor, the smaller the pixel, the higher the resolution required for the lens.

Tip: Increasing sensor resolution while maintaining sensor size to reduce costs requires lenses with higher MTFs to distinguish these smaller pixels. System costs should always be considered, as smaller pixel sizes at lower cost require higher resolution lenses.

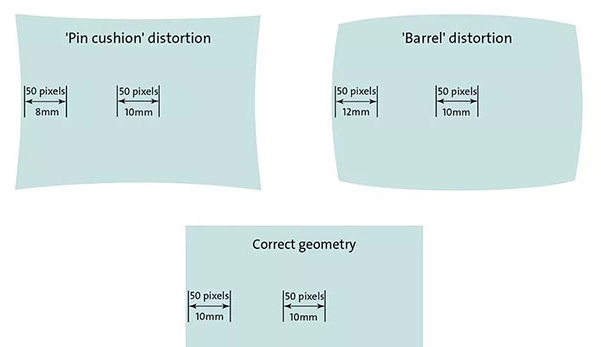

(2)Lens distortion

In addition to changes in resolution, all lenses will also be subject to certain spatial distortions. Figure 2 shows how to stretch or compress the image in a non-linear way, making accurate measurement of the entire sensor very difficult. Although there are some software methods that can solve this problem, they cannot consider the physical depth of the object, so it is better to choose a good quality low-distortion lens instead of trying to correct these errors in the software. As a general rule, a lens with a shorter focal length will have more distortion than a lens with a longer focal length because the light hits the sensor from a larger angle. Using more complex lens designs can maintain low distortion, and many lens manufacturers have been working hard on their optical designs to enable them to reduce spatial distortion to the order of 0.1%.

Tip: In order to minimize distortion at the lowest cost, a longer working distance will provide the best results.

3)Illumination uniformity

All images from the lens have vignetting, that is, the light intensity from the center to the edge of the image is reduced, which may affect the applicability of the lens. Lens shading is the shading of the edge of the image due to the beam being mechanically blocked (usually blocked by the lens holder). This mainly occurs when the image circle (or format) of the lens is too small for the size of the sensor. All lenses are affected by "Cos4 vignetting", this is because the light must travel a longer distance to reach the edge of the image and reach the sensor at a shallow angle. When the angle focuses light on the non-sensitive part of the sensor, there is a lens with a microlens on each pixel. It can also be minimized if the lens is stopped by two fs. By improving the uniformity of illumination across the sensor, lens manufacturers can eliminate the need for light intensity compensation, which may introduce noise in the image.

4)environmental impact

Many vision systems are deployed in manufacturing environments, which means they are exposed to a variety of environmental influences, from dirt, humidity and temperature to mechanical and electromagnetic effects. There are many protective covers available to prevent the intrusion of dust and moisture. The mechanical stability of the lens assembly is essential to avoid blur and ensure reliable and repeatable measurements. Most lenses used in machine vision applications are manufactured with metal housings and focusing mechanisms to ensure the stability of the lens. Many lenses also provide shock and vibration resistance, making them suitable for the harshest environments. Lens manufacturers have proposed a series of designs, some of which have been patented to limit the image displacement caused by the movement of the lens glass due to vibration and shock. These include the use of locking screws to prevent the movement of the focus and aperture, even the movement of a fixed aperture, and the bonding of all elements in the lens body.

5)Lens interface

Fixing the lens to the camera is achieved by using different standard lens interfaces. The most commonly used in machine vision applications is C-mount, which can benefit from a variety of lenses and accessories, including the ability to provide computer-controlled aperture and focus. The CS mount is not commonly used and is basically the same as the C-mount mount, but the flange focal length is shortened by 5mm. Smaller lens mount systems (such as S-mount) are usually used for board-level cameras and miniature cameras. These lenses only allow minimal adjustments. For large format sensors and line scan applications, larger F-mount systems can be used, although more powerful M42 mounts (sometimes called T-mounts) are increasingly used. But the large format lens does not support the ability to automatically control the aperture and focus. Telephoto lenses are also used in machine vision, with the longest focal length up to 600 mm. These large format lenses are mainly developed for professional photographers. They also include motorized apertures and zooms, and require special EF lens mounts. Currently, more and more machine vision cameras are manufactured with EF mounting functions and EF lenses, and their novel optical functions are provided to the wider machine vision market through the recent direct distribution agreement.

With so many machine vision lens options, choosing the best lens for a particular application is not easy. So it's important to think about the system as a whole. For example, many modern megapixel cameras use small sensor sizes to reduce costs, but the resulting small pixel sizes require higher quality and therefore more expensive optics. For some applications, choosing a camera that is more expensive, has more pixels, and has lower optical requirements may be beneficial, reducing the cost of the entire system. Working with expert vision technology vendors can mitigate risks in these decisions.

Vehviscam manufacture limited www.Vehviscam provides 1/1.8,2/3, 4/3 and 1 inch 8mm/12mm/16mm/25mm/35mm/50mm/75mm fixed focus industrial lenses with fair price and fast delivery, please source them online, thank you